Description

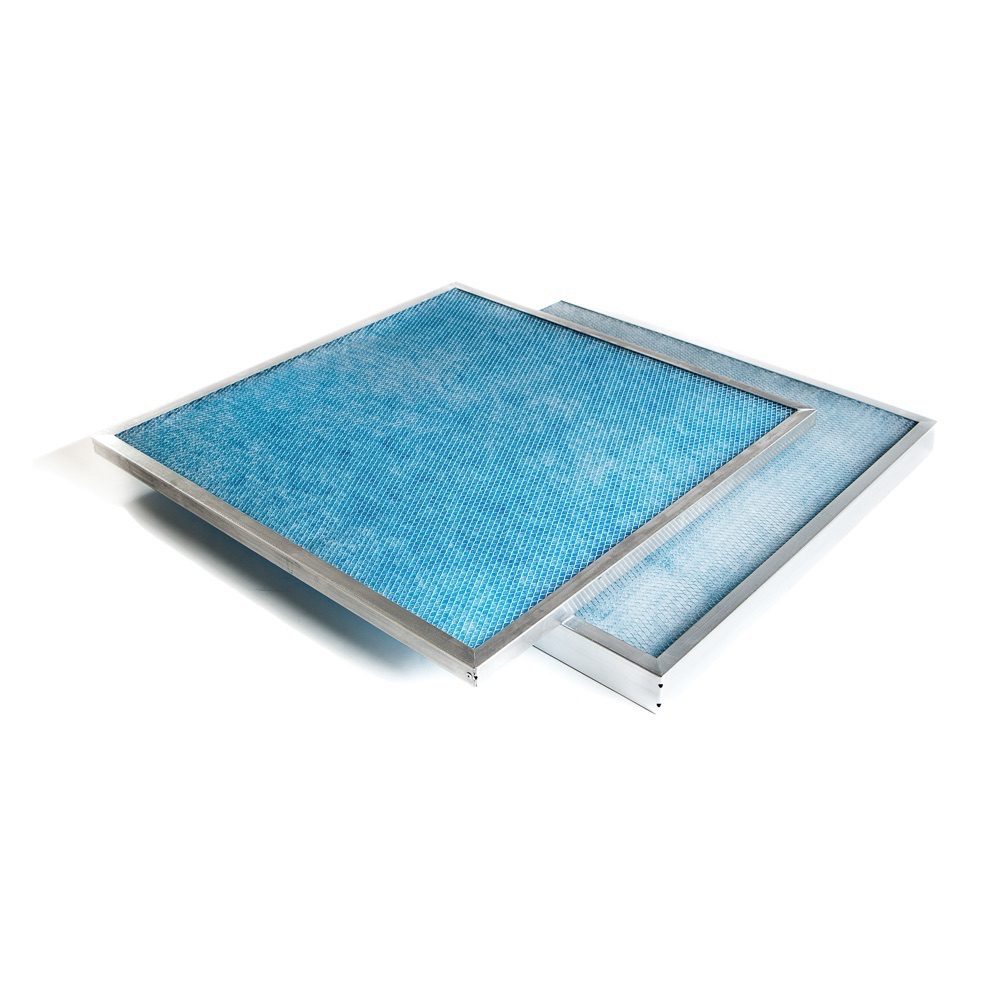

24x24x1 MERV 6 Washable Electrostatic Filter – Professional-grade aluminum-framed electrostatic filter rated to 150°F continuous operation, engineered for residential and light commercial HVAC systems requiring MERV 6 filtration with unlimited reusability.

- ✓ Aluminum frame with 4-ply electrostatic media for maximum particle capture

- ✓ UL 900 Class 1 certified for continuous operation at 150°F

- ✓ MERV 6 rated with 85% dust arrestance efficiency at rated airflow

- ✓ Washable with warm water only – unlimited cleaning cycles

- ✓ 1-inch depth (7/8″ actual) for standard residential filter slots

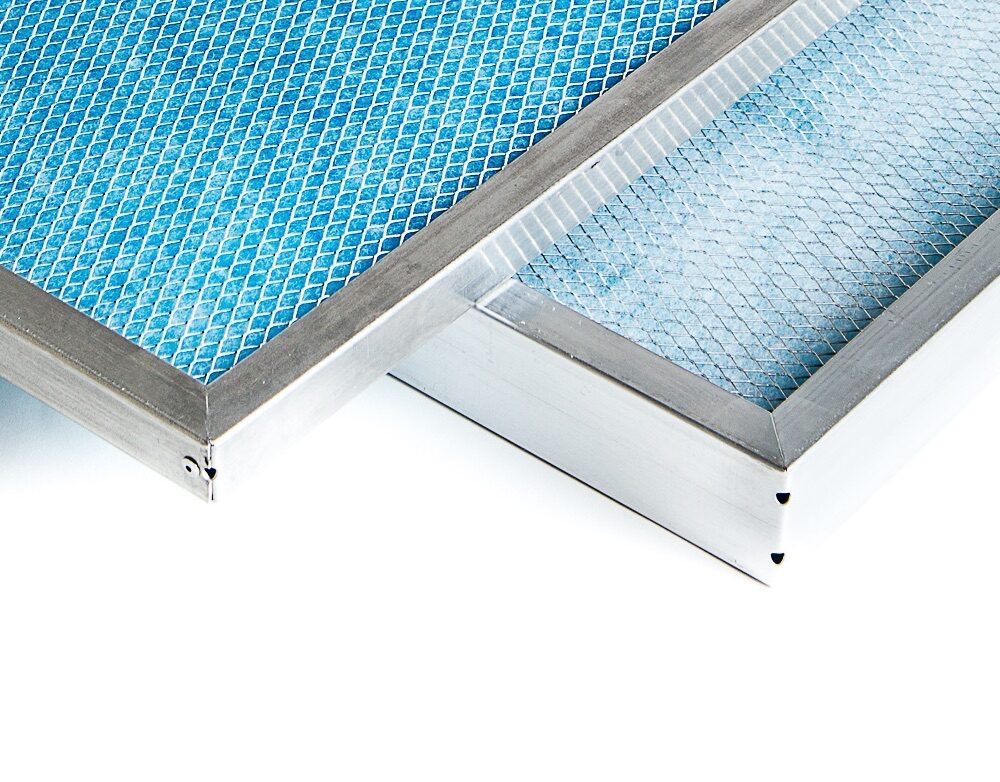

- ✓ Mitered corners with aluminum pop rivets and corner drain holes

- ✓ Made in USA – 5-10+ year service life with proper maintenance

- ✓ Protects downstream HEPA filters from large particles

Product Overview

The ECA102424 24x24x1 MERV 6 Washable Electrostatic Filter represents a breakthrough in residential and light commercial air filtration technology. Unlike traditional disposable filters, this UL 900 Class 1 certified aluminum-framed filter features advanced 4-ply electrostatic media engineered to capture airborne particles through electrostatic attraction, delivering superior MERV 6 performance with 85% dust arrestance efficiency while maintaining the durability and washability required for years of reliable service.

Designed specifically for standard HVAC systems operating at up to 150°F, this 1-inch depth filter (7/8″ actual dimension) provides the perfect balance between filtration efficiency and airflow performance. The precision-engineered aluminum frame with mitered corners and pop-riveted construction ensures dimensional stability across thousands of heating and cooling cycles, while three strategically placed corner drain holes facilitate complete water removal after washing, preventing moisture accumulation and extending filter life.

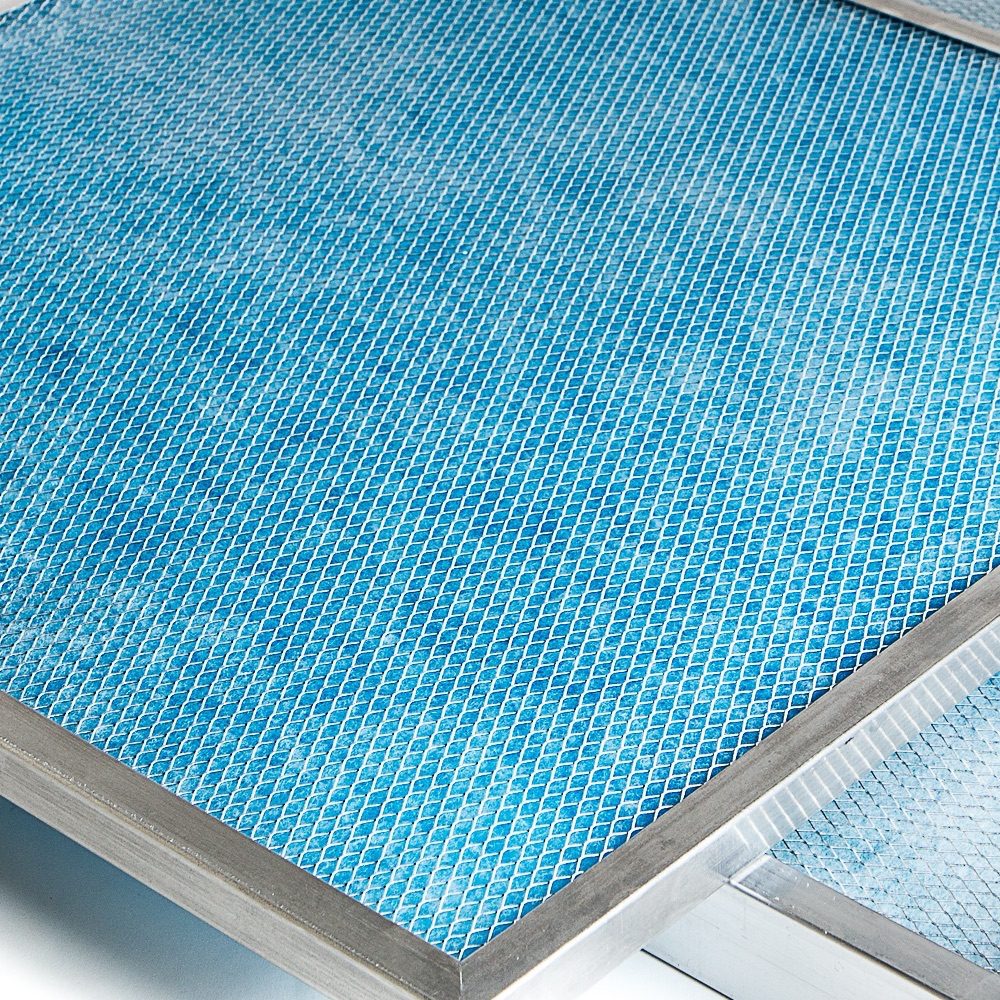

What sets the ECA102424 apart from conventional mesh pre-filters is its MERV 6 rating and 85% dust arrestance efficiency – achieved through a proprietary 4-ply electrostatic media construction combining polyester and polypropylene layers. This advanced design captures particles as small as 3-10 microns, including dust, pollen, lint, and mold spores, while maintaining the low pressure drop (0.02″ W.G. @ 300 FPM) essential for efficient HVAC operation. The result is cleaner indoor air, reduced load on downstream filters, and lower total system operating costs.

Key Benefits & Features

🎯 MERV 6 Certified Efficiency – Independently tested and certified to MERV 6 standards with 85% dust arrestance efficiency, capturing particles in the 3-10 micron range including dust, pollen, lint, and mold spores – far exceeding the performance of standard mesh pre-filters.

♻️ Unlimited Washability – Engineered for unlimited cleaning cycles with simple warm water rinsing – no detergents, no chemicals, no special equipment required. Maintains consistent filtration performance across years of service, eliminating recurring filter replacement costs.

🌡️ UL 900 Temperature Rating – UL 900 Class 1 certified for continuous operation at 150°F, suitable for both heating and cooling applications in residential and light commercial HVAC systems without performance degradation.

💨 Low Pressure Drop Design – Initial pressure drop of only 0.02″ W.G. @ 300 FPM rated airflow ensures maximum system efficiency, lower energy costs, and quieter operation compared to higher-resistance filters.

🏗️ Commercial-Grade Construction – Precision-mitered .030″ mill-finished aluminum frame with pop-riveted corners provides dimensional stability across thousands of thermal cycles. Three corner drain holes ensure complete water removal after washing, preventing moisture accumulation.

🛡️ Protects Downstream Filters – Captures large particles before they reach expensive HEPA or higher-MERV filters, dramatically extending downstream filter life and reducing system operating costs while maintaining superior MERV 6 efficiency.

🔬 4-Ply Electrostatic Media – Advanced electrostatic media construction combining polyester and polypropylene layers creates static charge that actively attracts and holds particles, achieving superior capture efficiency compared to mechanical screening alone.

📏 True-to-Size Dimensions – Nominal 24x24x1 inch size with actual dimensions of 23.5″ x 23.5″ x 7/8″ (±1/16″) ensures proper fit in standard residential filter tracks and commercial filter frames without gaps or bypass.

🇺🇸 Made in USA – Manufactured in the United States using domestically sourced aluminum and filter media, with rigorous quality control at every production stage ensuring consistent performance and dimensional accuracy.

⚡ Fast Payback – Typical payback period of 6-12 months compared to disposable MERV 6 filters, followed by 5-10+ years of cost-free filtration with proper maintenance – delivering exceptional long-term value.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | ECA102424 (EC Series – Aluminum Electrostatic) |

| Nominal Size | 24″ x 24″ x 1″ |

| Actual Dimensions | 23.5″ x 23.5″ x 7/8″ (±1/16″) |

| Frame Material | .030″ mill-finished aluminum |

| Filter Media | 4-ply electrostatic media (polyester + polypropylene layers) |

| Face Grids | 24 gauge aluminum expanded metal (both sides) |

| Frame Construction | Precision-mitered corners, aluminum pop rivets |

| Drainage | 3 corner drain holes for complete water removal after washing |

| Maximum Operating Temperature | 150°F continuous (UL 900 Classified) |

| MERV Rating | MERV 6 (independently tested per ASHRAE 52.2) |

| Dust Arrestance Efficiency | 85% average at rated airflow (ASHRAE 52.1) |

| Particle Capture Range | 3-10 micron particles (dust, pollen, lint, mold spores) |

| Dust Holding Capacity | 93 grams per square foot |

| Rated Airflow | 300 FPM (feet per minute) |

| Recommended Airflow Range | 250-350 FPM face velocity (rated 300 FPM) |

| Initial Pressure Drop | 0.02″ w.g. @ 300 FPM (clean filter) |

| Recommended Final Resistance | 0.50″ w.g. (water gauge) before cleaning |

| Weight | 2.5 lbs (dry) for 24x24x1, varies by size |

| Washability | Unlimited cycles with warm water rinse ONLY (no detergents or chemicals required) |

| Service Life | 5-10+ years with regular maintenance |

| Compliance | UL 900 Class 1, ASHRAE 52.1/52.2 tested |

| Country of Origin | Made in USA |

Understanding Filter Dimensions

The ECA102424 is described as a “24x24x1” filter using nominal dimensions – the industry-standard way to identify filter sizes. The actual dimensions are slightly smaller (23.5″ x 23.5″ x 7/8″) to ensure proper fit in standard filter tracks with typical 24″ x 24″ openings.

This sizing convention applies universally across the industry: a filter labeled 24x24x1 will have actual dimensions approximately 1/2″ smaller in width and height, and slightly less in depth. When measuring your filter slot, measure the opening size – that’s your nominal size. The filter’s actual dimensions will be sized to fit that opening properly with appropriate clearance for easy installation and removal.

Why 1-Inch Depth?

The 1-inch depth (7/8″ actual) serves as the standard depth for residential HVAC return filter grilles and the majority of commercial filter banks. This depth provides:

- Maximum Compatibility: Fits virtually all residential return air grilles and standard commercial filter tracks

- Optimal Balance: Sufficient media area for effective particle capture while maintaining low pressure drop

- Easy Handling: Lightweight construction simplifies installation, removal, and cleaning

- Cost Efficiency: Lower material costs compared to 2-inch depth filters while delivering excellent MERV 6 performance

For applications requiring higher dust holding capacity, the ECA202424 2-inch depth version offers 201 grams per square foot capacity with 84% dust arrestance efficiency, extending the interval between cleanings while maintaining the same 24×24 footprint.

Why Choose Washable Electrostatic Filters?

The decision to invest in a washable electrostatic filter delivers immediate and long-term value for homeowners and facility managers alike. While the initial cost exceeds disposable filters, the ECA102424’s unlimited washability eliminates recurring filter purchases for 5-10+ years of continuous service. A typical household spending $60-120 annually on disposable MERV 6 filters can expect complete payback within the first year, followed by years of cost-free filtration. For commercial applications with multiple filter locations, the savings multiply dramatically.

Beyond cost savings, washable electrostatic filters significantly reduce environmental impact. A single ECA102424 filter replaces 60-120 disposable filters over its service life, preventing hundreds of pounds of filter waste from entering landfills. The simple warm water cleaning process requires no chemicals or specialized equipment – just rinse, drain, air dry, and reinstall. This simplicity ensures consistent maintenance compliance, avoiding the performance degradation common when disposable filters are left in service too long due to procurement delays or budget constraints.

The MERV 6 efficiency rating places this filter in the ideal performance tier for residential and light commercial applications. It provides substantially better particle capture than standard fiberglass or basic mesh filters while maintaining the low resistance necessary for residential HVAC blowers. When installed as a primary filter or pre-filter protecting downstream HEPA units, the ECA102424 captures the bulk of airborne particles, dramatically extending the service life of expensive downstream filters and reducing system maintenance requirements.

EC Series vs. Traditional Pre-Filters

The EC Series electrostatic technology fundamentally differs from traditional aluminum mesh pre-filters. While mesh filters rely solely on mechanical screening with typical dust arrestance of 30-45%, the ECA102424’s electrostatic media actively attracts and holds particles through static charge, achieving 85% dust arrestance – nearly double the efficiency of comparable mesh filters. This enhanced capture occurs at a fraction of the pressure drop (0.02″ W.G. vs. 0.08″ W.G.), allowing HVAC systems to move more air with less energy while achieving superior filtration.

The 4-ply electrostatic media construction also provides significantly higher dust holding capacity (93 grams per square foot) compared to single-layer mesh screens. This translates to longer intervals between cleaning cycles and more consistent airflow performance as the filter loads with particles. The expanded aluminum face grids on both sides of the media protect the electrostatic layers from damage during handling and installation, ensuring consistent performance throughout the filter’s service life.

For applications requiring temperature resistance exceeding 150°F or exposure to harsh chemicals, AMFCO’s HI Series mesh filters with stainless steel construction remain the preferred choice. However, for the vast majority of residential and light commercial HVAC systems operating within normal temperature ranges, the EC Series delivers superior filtration efficiency, lower pressure drop, higher dust holding capacity, and simpler maintenance – all at a competitive price point that ensures rapid payback and long-term value.

Applications & Use Cases

The ECA102424 24x24x1 MERV 6 Washable Electrostatic Filter excels in residential and light commercial HVAC applications where superior particle capture, low maintenance costs, and environmental sustainability are priorities. The 4-ply electrostatic media construction achieves 85% dust arrestance, while the 150°F continuous temperature rating and MERV 6 efficiency make this filter ideally suited for:

Residential HVAC Systems

Primary Filtration for Central Air Systems: The ECA102424 serves as an excellent primary filter for whole-house heating and cooling systems, capturing 85% of airborne dust, pollen, and lint before these particles circulate through living spaces. The low 0.02″ W.G. pressure drop ensures efficient blower operation and quiet performance, while the unlimited washability eliminates recurring filter purchases for homeowners. Installation in the return air grille location provides easy access for quarterly cleaning cycles, and the MERV 6 efficiency significantly improves indoor air quality compared to basic fiberglass or mesh filters. The 5-10 year service life with proper maintenance makes this an ideal upgrade for homeowners seeking long-term value and reduced environmental impact.

Pre-Filter Protection for HEPA Systems: When installed as a pre-filter protecting downstream HEPA or MERV 13-16 filters in homes with occupants suffering from allergies or respiratory conditions, the ECA102424 captures the bulk of larger particles before they can load the expensive high-efficiency filters. This protective function dramatically extends HEPA filter life from typical 6-12 month replacement intervals to 2-3 years, delivering substantial cost savings. The electrostatic media’s 85% efficiency at the 3-10 micron range means large dust particles, pet dander, and pollen are captured at the pre-filter stage, while the HEPA filter focuses on sub-micron particles. The warm water cleaning process takes just minutes quarterly, versus the complexity and cost of HEPA filter replacement.

Light Commercial Applications

Office Buildings and Commercial Spaces: The ECA102424 provides ideal filtration for office HVAC systems, retail spaces, and commercial buildings where moderate traffic generates dust and requires regular air quality maintenance. The 24x24x1 size fits standard commercial filter banks, and facility managers appreciate the simplified maintenance – quarterly warm water rinsing eliminates procurement workflows, inventory management, and disposal logistics associated with disposable filters. For buildings with multiple filter locations, the cost savings multiply rapidly as a single cleaning schedule replaces continuous filter purchasing. The MERV 6 efficiency meets or exceeds minimum ventilation standards for commercial occupancy while maintaining the low pressure drop necessary for efficient system operation.

Light Manufacturing and Assembly: Clean assembly environments, electronics manufacturing (non-cleanroom), and light fabrication facilities benefit from the ECA102424’s ability to capture metal dust, lint, and airborne particulate generated by production processes. The aluminum frame and electrostatic media withstand the moderate dust loading typical in these environments, and the unlimited washability means filters can be cleaned weekly or bi-weekly during peak production periods without replacement costs. The 150°F rating accommodates warm air from production equipment, and the expanded aluminum face grids protect the electrostatic media from damage in industrial handling. For facilities operating single-shift or light production schedules, the ECA102424 delivers years of reliable service at a fraction of the cost of disposable filters.

Retail and Hospitality: Hotels, restaurants (front-of-house areas), retail stores, and hospitality venues require consistent air quality while controlling operational costs. The ECA102424’s MERV 6 efficiency captures dust and lint that would otherwise settle on merchandise, furniture, and surfaces, reducing cleaning labor while improving guest experience. The simple warm water cleaning process integrates easily into routine facility maintenance schedules, and the multi-year service life eliminates budget surprises from unexpected filter replacement needs. The made-in-USA construction ensures consistent availability without supply chain disruptions, critical for hospitality operations maintaining brand standards.

Applications Requiring Alternative Filters

While the ECA102424 excels in standard residential and light commercial applications, certain environments require alternative filtration solutions:

- Industrial ovens or high-temperature processes (>150°F): Applications exceeding the 150°F continuous rating require HI Series mesh filters rated to 275-900°F

- Heavy industrial environments: Facilities with heavy dust loading or abrasive particles may benefit from thicker mesh construction

- Harsh chemical environments: Consider HI Series stainless steel for superior corrosion resistance in chemical processing or industrial applications

- Cleanroom or medical-grade applications: MERV 6 efficiency is insufficient for environments requiring MERV 13+ or HEPA filtration; use ECA102424 as pre-filter only

- Marine or highly corrosive environments: Salt air, chemical vapors, or extreme humidity may require stainless steel construction

For guidance on filter selection for specialized applications, contact AMFCO technical support for application-specific recommendations based on your environmental conditions, temperature requirements, and filtration efficiency needs.

Maintenance & Cleaning

Proper maintenance of your ECA102424 MERV 6 Washable Electrostatic Filter ensures consistent filtration performance, maximum service life, and optimal HVAC system efficiency. The 4-ply electrostatic media achieves 85% dust arrestance and maintains its electrostatic charge across unlimited cleaning cycles when properly maintained. With a 150°F continuous temperature rating, this filter withstands typical HVAC operating conditions while delivering long-term value through its washable, reusable design.

Cleaning Frequency Recommendations

Residential Applications: Clean every 3-4 months (quarterly) for typical single-family homes with normal dust levels. Households with pets, high traffic, construction nearby, or allergy concerns should increase cleaning frequency to every 2-3 months. Monitor your HVAC system’s filter indicator light (if equipped) or check the filter monthly – when the surface appears visibly loaded with dust, it’s time for cleaning.

Commercial Applications: Clean every 1-2 months for office environments with moderate occupancy. High-traffic retail spaces, light manufacturing, or facilities in dusty locations may require monthly cleaning. Establish a calendar-based cleaning schedule and supplement with pressure drop monitoring if system instrumentation is available – clean when pressure drop reaches 0.40-0.50″ W.G.

Signs Your Filter Needs Cleaning:

- Visible dust accumulation on filter surface (surface appears gray or darkened)

- Reduced airflow from supply registers or return grilles

- HVAC system running longer cycles to maintain temperature

- Increased energy bills without explanation

- Filter indicator light (if equipped) showing service needed

- Pressure drop exceeding 0.40″ W.G. (if monitored)

Warm Water Cleaning Method (REQUIRED)

CRITICAL: The ECA102424 electrostatic filter MUST be cleaned with warm water ONLY. DO NOT use detergents, soaps, degreasers, or any cleaning chemicals. Chemical additives can damage the electrostatic media layers and permanently reduce filtration efficiency. DO NOT use high-pressure spray washers – excessive pressure can damage the delicate electrostatic media.

Step-by-Step Cleaning Process:

- Remove Filter from HVAC System: Turn off HVAC system (not required but recommended for safety). Note arrow direction on filter frame indicating airflow direction. Pull filter straight out from filter track or grille. Inspect frame and media for any damage before cleaning.

- Pre-Rinse (Outdoor Recommended): Take filter outdoors or to utility sink. Using garden hose with standard nozzle (NOT high-pressure spray), rinse filter from the clean side (downstream side – opposite the direction dust accumulated) working toward the dirty side. This pushes dust particles OUT of the filter rather than deeper into the media. Use moderate water pressure – sufficient to remove dust but gentle enough to avoid media damage.

- Warm Water Soak (For Heavy Loading): If filter is heavily loaded with dust or hasn’t been cleaned regularly, place in utility sink or large tub with warm (not hot) water for 10-15 minutes. This softens dust particles and makes them easier to rinse away. Do NOT add any cleaning products to the water – warm water only.

- Final Rinse: Continue rinsing both sides of filter until water runs clear and no dust particles are visible in rinse water. Pay special attention to corners and edges where dust may accumulate. Tilt filter at various angles to ensure complete rinse coverage across entire filter surface.

- Drain and Shake: Hold filter vertically and shake gently to remove excess water. The three corner drain holes will allow water to drain naturally from the frame channels. Continue shaking and tilting until no standing water remains in frame channels.

- Air Drying (REQUIRED): Stand filter on edge (leaning against wall or fence) in shaded area with good air circulation. Allow to air dry completely – typically 2-4 hours depending on humidity and temperature. DO NOT reinstall damp filter – moisture in HVAC system can promote mold growth. DO NOT use heat guns, hair dryers, or forced hot air – heat can damage electrostatic media. Patience during drying ensures filter performance and longevity.

- Reinstall Filter: Once completely dry, reinstall filter in HVAC system with arrow on frame pointing in correct airflow direction (toward blower/furnace, away from return air). Ensure filter is fully seated in tracks with no gaps around edges that would allow bypass. Resume normal HVAC operation.

Extended Service Life Tips

Never Skip Cleaning Cycles: Operating filter beyond recommended cleaning intervals forces HVAC blower to work harder, increases energy costs, and can overload filter media with particles that become more difficult to remove. Establish a calendar reminder for cleaning frequency and stick to the schedule – your HVAC system and energy bills will thank you.

Inspect During Each Cleaning: While cleaning, carefully inspect aluminum frame for any damage, bent corners, or separation at riveted joints. Check electrostatic media for tears, punctures, or delamination of the 4-ply layers. Inspect face grids for damage. Minor frame dents can often be straightened, but media damage or significant frame warping requires filter replacement.

Store Spare Filter (Optional): For commercial facilities or homes where downtime during cleaning is inconvenient, maintain a spare ECA102424 filter. This allows immediate filter swap during cleaning cycles, ensuring continuous HVAC operation while the dirty filter dries. Rotate between two filters to balance service life.

Document Cleaning History: Maintain a log of cleaning dates, approximate dust loading, and any observations about filter condition. This data helps optimize cleaning frequency and provides early warning of changes in indoor dust levels, HVAC system problems, or filter end-of-life indicators.

Expected Service Life

With proper maintenance following the warm water-only cleaning protocol, the ECA102424 typically delivers 5-10+ years of reliable service. Factors affecting service life include:

- Cleaning Frequency: Regular cleaning per recommendations extends filter life; allowing excessive dust buildup stresses filter media

- Cleaning Method: Warm water only preserves electrostatic charge; chemicals or high-pressure spray accelerate media degradation

- Handling Care: Gentle handling during removal, cleaning, and installation prevents frame damage and media tears

- Environmental Conditions: Moderate dust loading in typical residential/commercial environments; extreme dust or corrosive conditions may reduce service life

- HVAC System Condition: Well-maintained HVAC systems with proper airflow extend filter life; system problems that create excessive pressure drop stress filters

End-of-life indicators include: persistent difficulty removing dust during cleaning, visible media delamination or tears, loss of electrostatic attraction (dust falls off during handling), significant frame warping or damage, or reduced airflow even with clean filter. When these indicators appear, filter replacement is recommended.

Replacement Considerations

After 5-10 years of service, or if damage occurs, replacement filters are readily available. Order replacement ECA102424 filters directly from Metal Air Filters or through authorized distributors. Consider the ECA202424 2-inch depth version for upgrade to higher dust holding capacity (201 g/sq ft vs. 93 g/sq ft) if cleaning frequency has become burdensome – the 2-inch depth extends cleaning intervals while maintaining the same 24×24 footprint.

Installation Instructions

Proper installation of your ECA102424 24x24x1 MERV 6 Washable Electrostatic Filter ensures optimal filtration performance, maximum HVAC system efficiency, and long filter service life. The 4-ply electrostatic media provides 85% dust arrestance, while the 150°F continuous temperature rating handles typical HVAC operating conditions. Installation typically takes less than 5 minutes and requires no special tools or technical expertise.

Pre-Installation Checklist

Before installing your new ECA102424 filter, verify the following:

- ✓ Correct Size Confirmation: Verify your filter opening measures approximately 24″ x 24″ (nominal size). The ECA102424 actual dimensions of 23.5″ x 23.5″ x 7/8″ will fit standard 24x24x1 filter tracks with proper clearance.

- ✓ Clean Installation Area: Remove old filter and inspect filter tracks or grille slots for accumulated dust, debris, or damage. Vacuum or wipe tracks clean to ensure proper filter seating and prevent debris from being drawn into HVAC system during startup.

- ✓ Filter Track Condition: Inspect metal or plastic filter tracks for damage, warping, or missing retaining clips. Damaged tracks should be repaired before installing new filter to prevent gaps that allow air bypass around filter.

- ✓ Airflow Direction Identification: Locate the arrow printed on the filter frame indicating correct airflow direction. This arrow must point TOWARD your furnace/air handler (toward the blower) and AWAY FROM the return air opening where room air enters the system.

- ✓ HVAC System Off (Recommended): While not strictly required, turning off HVAC system during filter change prevents dust disturbance and makes installation easier. Turn off at thermostat or circuit breaker.

Installation Steps

Step 1: Remove Packaging and Inspect Filter

Carefully remove the ECA102424 filter from its packaging. Inspect the aluminum frame for any shipping damage – check corners, rivets, and frame straightness. Examine electrostatic media for tears or damage. Verify expanded aluminum face grids are intact on both sides. If any damage is observed, contact supplier immediately for replacement before installation.

Step 2: Identify Airflow Direction

Locate the directional arrow printed on the filter frame edge. This arrow indicates the correct airflow direction and MUST point toward your blower/furnace. Incorrect orientation will reduce filtration efficiency and may damage the electrostatic media over time. Remember the simple rule: arrow points TOWARD equipment, AWAY FROM return air.

Step 3: Position Filter in Opening

For return air grille installations (most residential applications), align the filter with the grille opening, ensuring the arrow points toward the ductwork/equipment side (away from the room). The filter should slide easily into the tracks or slots with minimal force. For filter rack installations (commercial applications), slide filter into rack channels ensuring full engagement on all four sides.

Step 4: Verify Proper Seating

Once inserted, verify the filter is fully seated in all four tracks with no visible gaps around the perimeter. Gaps allow air bypass, reducing filtration effectiveness. If filter doesn’t seat properly, remove and inspect tracks for debris or damage. The filter should fit snugly but not require excessive force – proper dimensional tolerance ensures easy installation and removal for cleaning.

Step 5: Secure Grille or Access Door

Replace return air grille (if removed) ensuring grille is fully seated against wall or ceiling. Tighten mounting screws firmly but avoid overtightening which can warp grille. For commercial filter racks, close and secure access door or panel per manufacturer’s instructions.

Step 6: Resume HVAC Operation

Turn HVAC system back on at thermostat or circuit breaker. Listen for normal system operation – absence of whistling, rattling, or unusual noises indicates proper filter installation. Stand near return air grille and verify strong air draw confirming filter is not blocking airflow. Check supply registers for normal airflow volume.

Common Installation Mistakes

❌ Incorrect Airflow Direction: Installing filter backwards (arrow pointing wrong direction) is the most common error. Always verify arrow points TOWARD equipment, AWAY FROM return air. Incorrect orientation reduces efficiency and may damage filter over time.

❌ Gaps Around Filter Perimeter: Filter not fully seated in tracks allows air bypass, dramatically reducing filtration effectiveness. Ensure filter is pushed fully into all four tracks with no visible gaps. If gaps persist, tracks may be damaged or wrong filter size was ordered.

❌ Installing Wet Filter: Never install filter before it is completely dry after cleaning. Moisture in HVAC system promotes mold growth and can damage blower bearings. Always allow 2-4 hours air drying after cleaning before reinstallation.

❌ Forcing Filter Into Undersized Opening: Filter should slide easily into correct-sized opening. If excessive force is required, you may have wrong filter size. Verify opening dimensions before forcing filter, which can damage frame or media.

❌ Operating Without Filter: Never operate HVAC system without filter in place, even temporarily. Unfiltered air carries dust directly to blower wheel, heat exchanger, and evaporator coil, causing performance degradation and expensive cleaning or component replacement.

Multiple Filter Locations

If your HVAC system has multiple return air openings, install ECA102424 filters in ALL locations for complete system protection. Operating some returns without filters creates unfiltered air pathways that bypass filtration entirely. For systems with different-sized returns, order appropriate ECA-series filters for each size – maintaining consistent MERV 6 filtration across all returns ensures balanced system performance.

First-Time Startup

During the first 24-48 hours after installing a new ECA102424 filter, the electrostatic media conditions itself to your HVAC airflow patterns, and the aluminum frame thermally stabilizes. You may notice a slight “new filter” smell during this initial period – this is normal and will dissipate quickly. Monitor system operation during this period to ensure proper airflow and listen for any unusual noises indicating installation problems.

After the first month of operation, perform an early inspection and cleaning cycle. This removes any manufacturing residue or initial dust loading, and allows you to verify the filter is performing as expected. After this initial cleaning, establish regular quarterly cleaning schedule for residential applications or monthly schedule for commercial use.

Professional Installation

While ECA102424 filter installation is straightforward for most homeowners, professional HVAC technician installation may be preferred for:

- Commercial installations with specialized filter racks or hard-to-access locations

- Systems with damaged or non-standard filter tracks requiring repair

- First-time installations where HVAC system configuration is unclear

- Integration with building automation or filter monitoring systems

HVAC service companies are familiar with washable filter installation and can verify proper system operation, airflow balance, and establish maintenance schedules appropriate for your application.

Related Washable Filters

Looking for similar MERV 6 electrostatic filters in different sizes? All EC Series filters feature 4-ply electrostatic media construction for superior dust capture:

- 16x20x1 MERV 6 Electrostatic Filter (ECA101620) – Ideal for smaller residential HVAC units with 85% dust arrestance

- 20x20x2 MERV 6 Electrostatic Filter (ECA202020) – Standard commercial size with 84% dust arrestance and enhanced dust holding

- 16x25x1 MERV 6 Electrostatic Filter (ECA101625) – Perfect for elongated filter banks and commercial applications

- 20x25x1 MERV 6 Electrostatic Filter (ECA102025) – Versatile size for commercial rooftop units with enhanced dust holding

- 12x24x1 MERV 6 Electrostatic Filter (ECA101224) – Compact size for split systems and smaller filter banks

- 24x24x2 MERV 6 Electrostatic Filter (ECA202424) – Same footprint as ECA102424 but with 2-inch depth for enhanced dust holding capacity (201 g/sq ft)

- 24x24x1 High-Temp Alternative (HIA102424) – HI Series alternative for applications exceeding 150°F (rated to 275°F)

Complementary Products

Build a complete multi-stage filtration system with these complementary filters and accessories. The ECA102424 features 4-ply electrostatic media with 85% dust arrestance and 150°F temperature rating, and pairs well with:

Foam Secondary Filters (MERV 4)

- 24x24x1 Two-Stage Foam Filter (HFA102424) – Dual-layer polyurethane foam provides 65% dust arrestance at 3-10 microns, ideal as secondary filter protecting downstream equipment

- 24x24x2 Two-Stage Foam Filter (HFA202424) – Enhanced dust holding capacity with 2-inch depth, extends cleaning intervals for commercial applications

- 20x20x1 Two-Stage Foam Filter (HFA102020) – Smaller footprint for compact HVAC installations or staged filtration systems

Additional Electrostatic Filters (MERV 6)

- 20x20x1 MERV 6 Electrostatic (ECA102020) – Match ECA102424 performance in different size for multi-filter systems

- 24x24x2 MERV 6 Electrostatic (ECA202424) – Upgrade option with double the dust holding capacity (201 g/sq ft vs. 93 g/sq ft)

- 16x25x1 MERV 6 Electrostatic (ECA101625) – Alternative size for systems with multiple return locations

Pad Holding Frames & Accessories

- 24x24x1 Galvanized Holding Frame (HPGG102424) – Secure mounting frame for commercial filter banks, accommodates ECA102424 and disposable media pads

- 24x24x2 Galvanized Holding Frame (HPGG202424) – 2-inch depth frame for higher capacity installations or staged filtration

- R8 Side-Access Filter Rack – Professional-grade aluminum filter rack system for easy maintenance access in commercial installations

Multi-Stage Filtration Strategy: For maximum indoor air quality and equipment protection, consider installing ECA102424 as Stage 1 (primary pre-filter) followed by HFA102424 foam filter as Stage 2 (secondary protection) or higher-MERV disposable filters as final stage. This cascading approach captures progressively smaller particles while extending the service life of each filtration stage and reducing total system maintenance costs.

Frequently Asked Questions

Q: How often should I clean the ECA102424 filter?

A: For residential applications, clean every 3-4 months (quarterly) under normal conditions. Homes with pets, high traffic, nearby construction, or allergy concerns should clean every 2-3 months. Commercial applications typically require cleaning every 1-2 months. The best indicator is visual inspection – when the filter surface appears loaded with dust or airflow seems reduced, it’s time for cleaning. Most residential users find quarterly cleaning adequate, while commercial facilities often establish monthly cleaning schedules.

Q: Can I use soap or detergent to clean this filter?

A: NO. The ECA102424 must be cleaned with warm water ONLY. Never use soaps, detergents, degreasers, or any chemical cleaning products. The 4-ply electrostatic media relies on specific material properties to generate static charge that attracts particles. Chemical additives can damage these properties, permanently reducing the filter’s efficiency from 85% down to levels comparable to basic screening. Additionally, avoid high-pressure spray washers – use standard garden hose pressure or gentle sink spray only. The warm water-only cleaning protocol preserves the electrostatic charge and ensures the filter maintains MERV 6 performance across its entire 5-10 year service life.

Q: What size filter do I need? How do I measure my filter opening?

A: The ECA102424 is sized using nominal dimensions (24x24x1), which refer to the filter opening size, not the actual filter dimensions. To measure your opening, remove your old filter and measure the width and height of the opening where the filter sits – that’s your nominal size. Don’t measure the old filter itself (which will be slightly smaller). The ECA102424 actual dimensions are 23.5″ x 23.5″ x 7/8″ – approximately 1/2″ smaller than nominal to ensure proper fit. If your opening measures approximately 24″ x 24″, order the ECA102424. The slight size difference is intentional and industry-standard, ensuring filters slide easily into openings while maintaining proper seal against bypass.

Q: How long will this filter last before I need to replace it?

A: With proper maintenance (warm water cleaning only, regular cleaning frequency, gentle handling), the ECA102424 typically delivers 5-10+ years of reliable service. Some users report 15+ years in light-duty residential applications. Service life depends on cleaning frequency, cleaning method adherence, handling care, and environmental conditions. Signs of end-of-life include: persistent difficulty removing dust during cleaning, visible media delamination or tears, loss of electrostatic attraction (dust falls off during handling), significant frame warping, or reduced airflow even with clean filter. Most residential users achieve 8-10 years with quarterly cleaning; commercial applications with monthly cleaning may see 5-7 years depending on dust loading.

Q: Will this filter fit my furnace/air conditioner?

A: The ECA102424 fits any HVAC system with a 24x24x1 filter opening, including furnaces, air conditioners, heat pumps, air handlers, and rooftop units. The filter is designed for residential central air systems and light commercial HVAC equipment. To confirm compatibility, check three factors: (1) Filter opening size – measure approximately 24″ x 24″, (2) Depth clearance – ensure at least 1″ depth available in filter track or grille, (3) Temperature rating – system must operate below 150°F continuous (suitable for all standard residential/commercial HVAC). If your current filter is labeled 24x24x1, the ECA102424 is a direct replacement upgrade. For commercial installations with specialized filter racks, verify rack accepts standard dimensional filters.

Q: How much money will I save compared to disposable filters?

A: Savings depend on your current filter costs and replacement frequency. A typical household replacing MERV 6 disposable filters quarterly spends $60-120 annually ($15-30 per filter × 4 changes). The ECA102424’s purchase price is typically recovered within 6-12 months, after which you enjoy 5-10+ years of cost-free filtration (aside from minimal water costs during cleaning). Over 10 years, this represents $600-1,200 in savings for a single filter location. Commercial facilities with multiple filter locations see proportionally higher savings – a building with 10 filter locations can save $6,000-12,000 over 10 years. Additional savings include reduced HVAC service calls (cleaner coils and blower wheels), lower energy costs (consistent low pressure drop), and extended downstream filter life if using multi-stage filtration.

Q: Is MERV 6 enough for allergies and air quality concerns?

A: MERV 6 provides significant improvement over basic fiberglass or mesh filters (typically MERV 2-4), capturing 85% of particles in the 3-10 micron range including large dust, pollen, lint, and mold spores. For mild to moderate allergy concerns, MERV 6 as primary filtration often provides noticeable improvement in air quality. However, severe allergies, asthma, or respiratory conditions typically require MERV 11-13 or HEPA filtration for sub-micron particle capture. In these cases, use the ECA102424 as a pre-filter protecting downstream HEPA or high-MERV disposable filters. This dual-stage approach captures large particles at the pre-filter (extending expensive HEPA filter life from 6-12 months to 2-3 years) while the HEPA filter handles sub-micron allergens. Consult with an allergist or HVAC professional to determine appropriate filtration level for your specific health needs.

Q: Can I install this filter myself or do I need a professional?

A: Most homeowners can install the ECA102424 filter themselves in under 5 minutes with no tools required. The process is identical to changing a disposable filter: (1) Turn off HVAC system (optional but recommended), (2) Remove old filter, (3) Note arrow direction on new filter frame, (4) Slide new filter into tracks with arrow pointing toward furnace/blower (away from return air), (5) Ensure filter is fully seated with no gaps, (6) Turn system back on. If you’ve successfully changed a disposable filter before, you can install the ECA102424. Professional installation may be preferred for commercial applications with hard-to-access locations, specialized filter racks, or if you’re unsure about your system configuration. HVAC technicians are familiar with washable filters and can verify proper installation during routine service calls.

Q: What’s the difference between 1-inch and 2-inch depth filters?

A: Both 1-inch (ECA102424) and 2-inch (ECA202424) filters offer MERV 6 efficiency, but the 2-inch version provides higher dust holding capacity: 201 grams per square foot vs. 93 g/sq ft for the 1-inch. This translates to longer intervals between cleaning cycles – potentially extending quarterly cleanings to semi-annual cleanings in residential applications. The 2-inch filter has slightly lower dust arrestance (84% vs. 85%) due to media configuration but holds more than double the dust before requiring cleaning. Choose 1-inch depth (ECA102424) for standard residential return air grilles and cost-sensitive applications. Choose 2-inch depth (ECA202424) for commercial applications requiring extended cleaning intervals, high-traffic environments, or when your filter tracks accommodate 2-inch depth. Both filters share the same 24×24 footprint and require the same warm water cleaning process.

Q: Will this filter reduce my energy bills?

A: Yes, in multiple ways. First, the ECA102424’s low pressure drop (0.02″ W.G. when clean) requires less blower energy than higher-resistance filters, reducing HVAC operating costs. Second, regular cleaning maintains this low resistance – disposable filters left in service too long (common due to forgetfulness or procurement delays) create high resistance forcing blowers to work harder and consume more energy. Third, cleaner HVAC components (coils, blower wheels, ductwork) resulting from effective filtration improve heat transfer efficiency and airflow, reducing heating and cooling costs. Fourth, protecting downstream components from dust buildup prevents efficiency degradation over time. While difficult to quantify precisely (varies by system size, runtime, local energy costs), many users report 5-10% reduction in HVAC-related energy costs after switching to washable filters with consistent maintenance schedules. The combination of low pressure drop and consistent maintenance compliance delivers measurable energy savings over disposable filter alternatives.

Why Choose AMFCO Metal Air Filters?

For over four decades, AMFCO has specialized in manufacturing premium washable metal air filters for residential, commercial, and industrial applications. Unlike mass-market filter suppliers offering commodity disposable products, we focus exclusively on engineered washable filtration solutions that deliver superior long-term value, environmental sustainability, and performance reliability. Every ECA102424 filter is manufactured in the USA using domestically sourced aluminum and filter media, with rigorous quality control ensuring dimensional accuracy, proper electrostatic media construction, and consistent MERV 6 performance.

Our EC Series electrostatic filters represent the culmination of decades of filtration engineering experience, combining advanced 4-ply electrostatic media technology with precision aluminum frame construction rated to 150°F continuous operation. The result is a filter that outperforms traditional mesh pre-filters (85% vs. 30-45% efficiency) while maintaining lower pressure drop, higher dust holding capacity, and simpler maintenance requirements. We’ve eliminated the compromise between filtration efficiency and system performance – the ECA102424 delivers both.

When you choose AMFCO washable filters, you’re making a long-term investment in indoor air quality, HVAC system protection, and environmental responsibility. The ECA102424’s 5-10 year service life replaces 60-120 disposable filters, eliminating hundreds of pounds of filter waste while saving hundreds of dollars in recurring filter costs. The simple warm water cleaning process requires no special equipment or chemicals – just rinse, dry, and reinstall. This simplicity ensures consistent maintenance compliance, avoiding the performance degradation common when disposable filters are neglected.

We stand behind our products with responsive technical support, application engineering guidance, and a commitment to customer satisfaction. Whether you’re a homeowner seeking cleaner indoor air and lower operating costs, a facility manager optimizing maintenance budgets, or an HVAC professional specifying reliable filtration solutions for clients, AMFCO delivers the products, expertise, and support you need. Order your ECA102424 today and experience the difference that professional-grade washable filtration makes in your HVAC system performance and operating costs.

Ready to upgrade to washable electrostatic filtration?

Order ECA102424 Now